Liquid Oxygen Tank Pressure Builder

Liquid storage is less bulky and less costly than the equivalent capacity of high pressure gaseous storage.

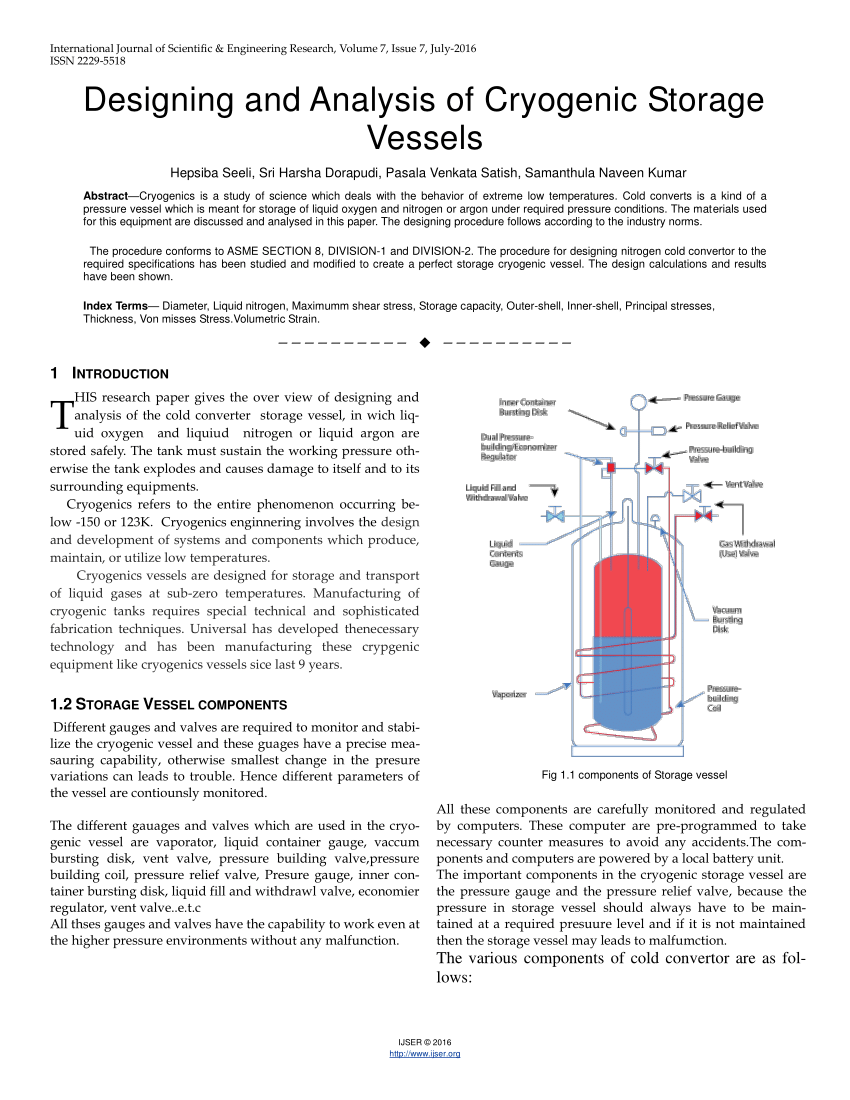

Liquid oxygen tank pressure builder. Liquid oxygen transport tank is made up of high quality insulating material which separates the space between inner and outer vessel. The economizer circuit minimizes product loss. Oxygen is often stored as a liquid although it is used primarily as a gas. A typical storage system consists of a cryogenic storage tank.

The liquid is vaporized in the pressure building vaporizer. Pressure by removing liquid from the bottom of the tank and passing it through a coil that is soldered to the outer skin of the tank. The gas use valve allows gas to flow from the tank. To draw liquid close the gas use and pressure building valves and open the liquid use valve.

A pressure building regulator controls the gas flow in this circuit. The exposure to heat from contact to the tank exterior causes the liquid to convert to a gaseous state as it moves back to the top of the tank. Opening the pressure building valve increases tank pressure to normal operating levels. The hp series cylinders are factory set to automatically maintain a normal operating pressure between 300 and 315psig 2 07 2 17mpa with the pressure building portion set as 300psig 2 07mpa and the economizer portion set 315psig 2 17mpa.

Handling of liquid nitrogen argon and oxygen with the tank. The pressure building regulator opens. Tank pressure decreases as product is used. The pressure building regulator maintains a preset vessel pressure during the liquid withdrawal as long as a sufficient liquid level is present in the container and the pressure building valve is open.

Dispense liquid oxygen nitrogen argon carbon dioxide and nitrous oxide. The pressure gauge indicates pressure inside the inner tank. The tank is double walled and is evacuated to high vacuum to prevent evaporation losses. It should be thoroughly read and understood by anyone that operates the equipment.

The resulting gas is sent to the top of the tank increasing the tank pressure. The liquid is withdrawn from the tank. It is equipped with automatic pressure build up regulator. If a different pressure setting is required the pressure building regulator can be adjusted.