Lock Out Tag Out Locks Color Code

Durable polypropylene resists rust cracking chemicals and solvents.

Lock out tag out locks color code. Is it mandatory that color coding be applied to the lockout tagout tags for an electric utility provider. Lockout tagout locks lockout locks keyed different safety padlocks loto locks for lock out tag out. Osha does not mandate specific color coding for the lock out tag out tags. Color coded locks can also tell you who is still working on a machine at a glance improving the visibility of the lockout process.

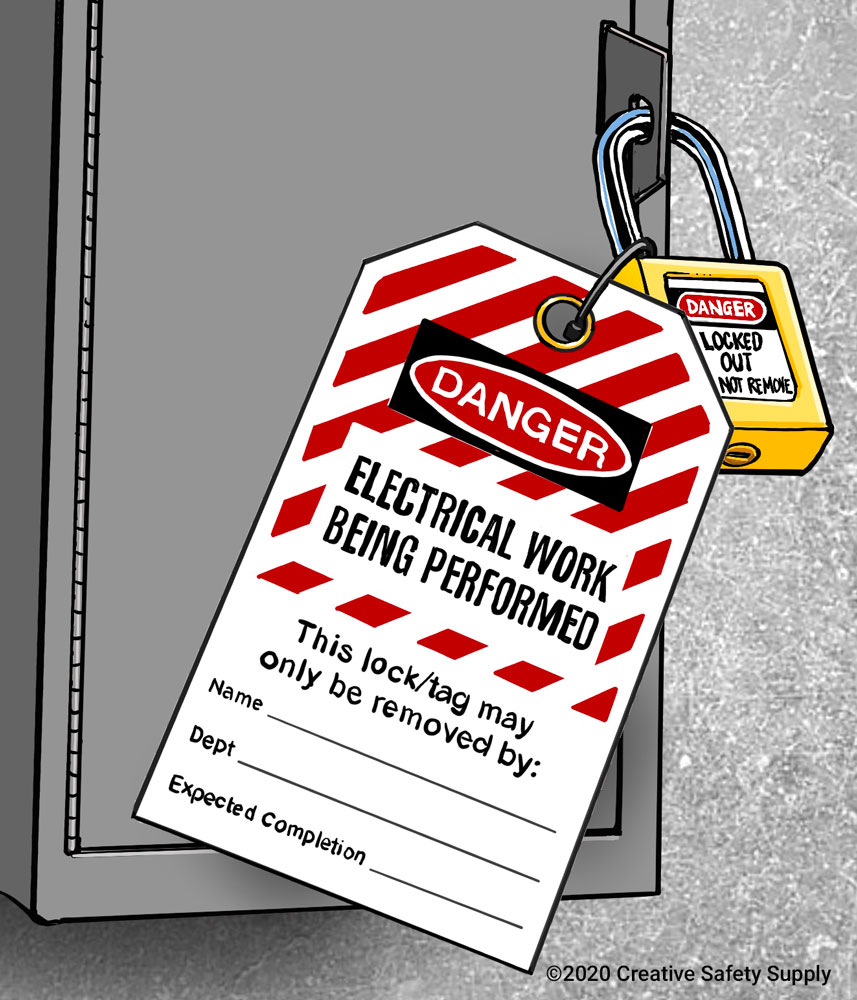

Attaching lockout tags to the shackles of locks presently in use can also prove a cost effective way to conform to safety standards. Help everyone identify lockout points in your facility with bold and legible labels. Place lock out snugly over valve then slide locking mechanism into place and then secure tightly with padlock. Learn more about how each approach may benefit your lockout tagout program.

1910 269 d 3 ii b leaves it to the electric utility to determine the color coding for. The national electrical code nec recently changed the requirement for breakers in applications that require a lockout and tagout loto provision. 99 1 90 oz 39 99 39 99. 4 5 out of 5 stars 13.

5 coupon applied at checkout save 5 with coupon. Our lockout point labels are printed with bright hard to miss colors that make spotting lockout points easy. If a disconnecting means is required to be lockable open elsewhere in the code it shall be capable of being locked in the open position. In addition these custom cabinets also prove ideal to safeguard keys of padlock stations and group lockout kits to ensure lockout devices are deployed and removed in a strictly controlled manner.

Get it as soon as thu oct 1. Free shipping by amazon. Proper lockout tagout loto practices and procedures safeguard workers from the release of hazardous energy. Color coding larger organizations have benefited from color coding locks by trade or location to help keep equipment organized.

Lock out tag out loto is a safety procedure used in industry and research settings to ensure that dangerous machines are properly shut off and not able to be started up again prior to the completion of maintenance or repair work it requires that hazardous energy sources be isolated and rendered inoperative before work is started on the equipment in question. Don t miss the free webinar improving access to loto equipment means time saved and no excuses. Lockout and tagout points can be small inconspicuous and out of sight in bustling dimly lit industrial facilities. The osha standard for the control of hazardous energy lockout tagout 29 cfr 1910 147 for general industry outlines specific action and procedures for addressing and controlling hazardous energy during servicing and maintenance of machines and equipment.