Machine Condition Monitoring Techniques

Machine tool condition monitoring.

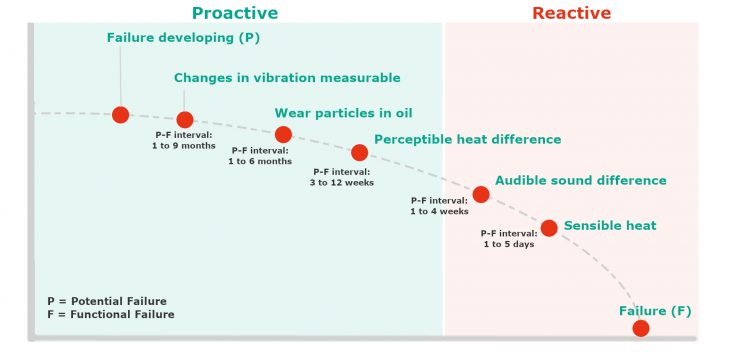

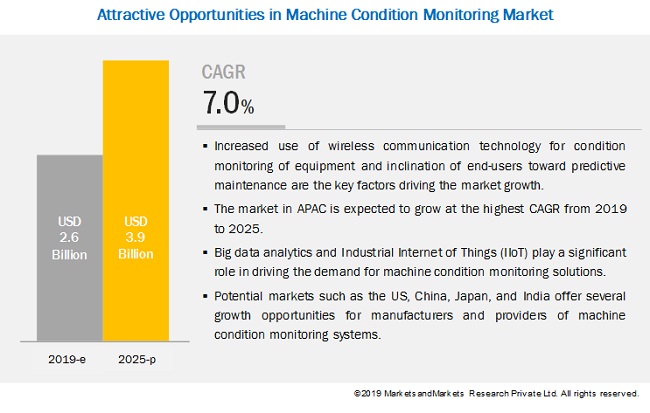

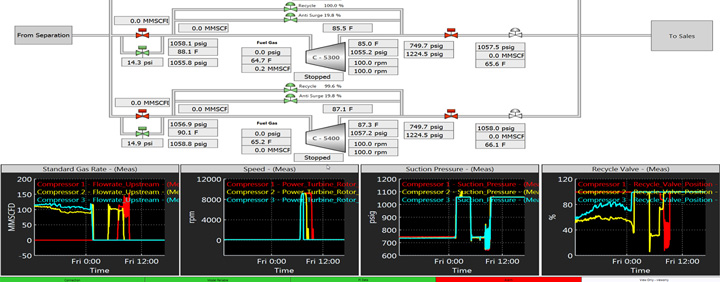

Machine condition monitoring techniques. The following list includes the main condition monitoring techniques applied in the industrial and transportation sectors. Practical notes on availability improvement plans condition monitoring techniques predictive maintenance methods trouble shooting techniques and smart operation are discussed in the article. Condition monitoring of machine using irt. Condition based monitoring can detect possible faults well before they are likely to happen so is the ideal method of keeping a machine in maximum condition.

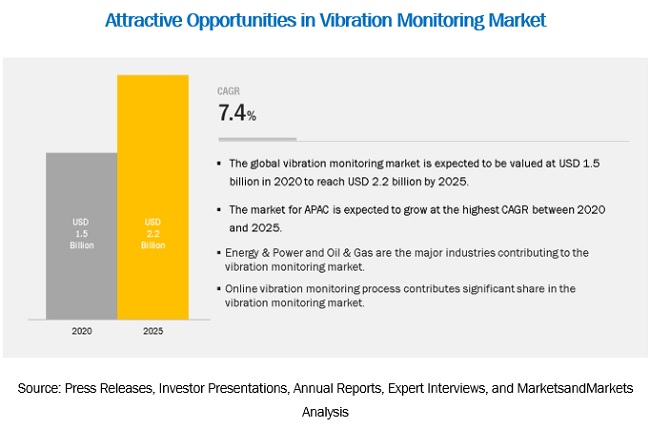

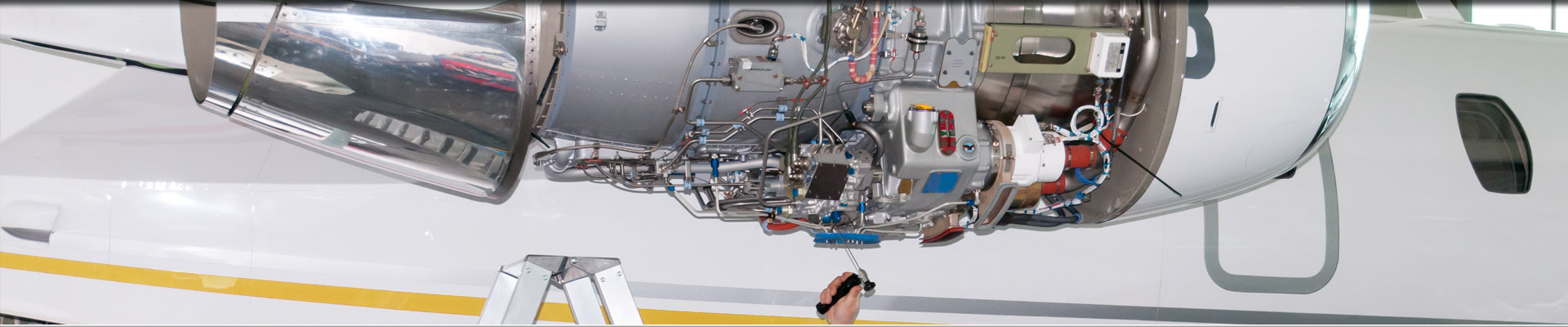

Thermography for condition monitoring. Condition monitoring techniques course description this training program is designed to provide valuable information on machine condition monitoring as a tool for quickly identifying and correcting the root causes of machinery problems achieving precise operation and improving machinery performance. Advanced condition monitoring methods have been used to operate rotating machines reliably and efficiently. Condition monitoring techniques are normally used on rotating equipment and other machinery pumps internal combustion engines presses.

There are two approaches for temperature measurement. Techniques of wear debris analysis and some of the nondestructive test ndt techniques for condition monitoring like ultrasonics and radiography. Condition monitoring overview vibration analysis and diagnostics lubricant analysis acoustic emission infrared thermography ultrasound oil condition sensors motor condition. Condition monitoring of an electrical machine using irt is a technique that relies majorly on temperature measurement of the equipment under test.

Basics of signal processing and instrumentation which are essential for monitoring the health of machines. Vibration based condition monitoring vcm is a well known and well accepted method for the health monitoring of rotating machines in industries. 2 oil analysis condition monitoring techniques. Condition monitoring of rotating machines enables early detection of faults and avoidance of unexpected machinery breakdowns.

Complete list of condition monitoring techniques ferrography presence of water viscosity kinematic viscosity test icp or atomic emissions spectroscopy to identify presence of contaminants dielectric strength test microbial analysis particle quantification index iron content fourier. 1 1 aspects of oil analysis. By using advanced tools such as thermography laser alignment and vibration analysis it is possible to see a picture of the machine s performance and that of all of its separate components over time from one monitoring process to the other. The use of condition monitoring allows maintenance to be scheduled or other actions to be taken to prevent failure and avoid its consequences.

Special emphasis is given to trouble shooting data interpretation health assessment and.